Capabilities

Multi-Axis Milling

Our advanced equipment is capable of longer time in the cut, less material handling and setup, and a more precise product. This also allows us to produce more hours during the days, weeks, and months to maximize production and efficiencies.

Our personnel are cross trained to work on a vast range of machining projects, from small precision tooling to manifolds over 800 lbs.

Our current milling centers give us a 3, 4, and 5 axis machining area up to 30” (X) X 50” (Y) X 25” (Z) and material up to 1000 lbs/ea.

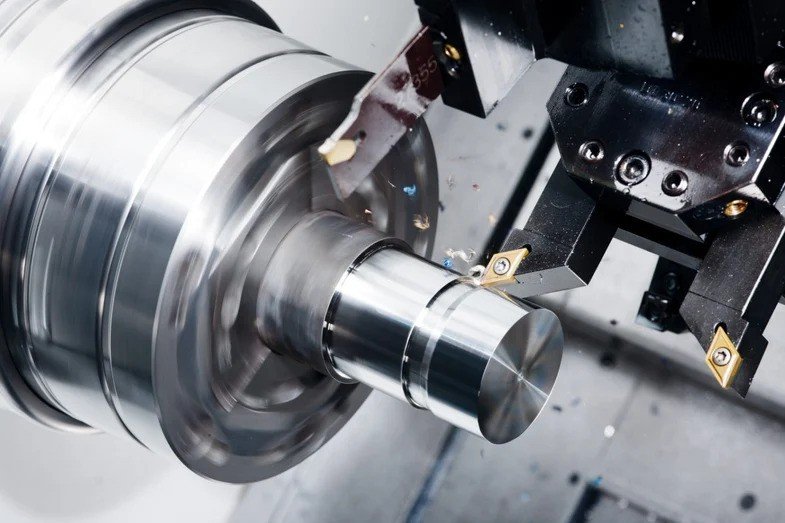

Multi-Axis Turning

Our turning centers provide close tolerance machining down to .0002 and do both complete and secondary operations to fit any customer needs.

Our broad range of turning centers provide opportunities for small size, high-production capabilities to large, heavy billet and casting projects.

Our current turning centers give us a machining area of 16” diameter X 40” (Z) and material up to 200 lbs/ea while still allowing for small parts < .25″ diameter.

Assembly

Let us take your components to the next level. With an extensive network of metal finishing vendors, hardware suppliers, and a dedicated assembly area, we can provide value added services to deliver an assembled product per your supplied work instructions or help you design an assembly process for a new product.

Our assembly area includes a vast array of hardware and fasteners, treatment oven up to 200 C, optical inspection options, torque wrenches and tools, and packaging options to meet your needs.

Prototype

We have the ability to prove out your design before you scale up production. With our extensive CAD/CAM experience, programming knowledge, and setup acumen, we’ll create short-run parts quickly for your evaluation.

Our CAD/CAM system allows us to track revision changes and follow you along the design process, as changes are needed to deliver the product you need.

On top of our prototyping abilities, we can also include the following processes when requested:

☑ Material Certification

☑ Metal Finishing Certification

☑ Mechanical Property Test Reports

☑ First Article Inspection Reports

☑ Certificate of Conformance

Production

Once your design has been proven, let us scale up to meet your demands.

We’ll design custom tooling and a complete machine setup to be sure your product is manufactured efficiently and affordably. Whether it’s five or five-thousand pieces, we can cater to one-time orders, weekly or monthly deliveries, or long-term delivery schedules. At Imagineering Machine Inc, we stay flexible enough to meet your short and long-term goals.

Metal Finishing

We believe offering a full-service solution to our customer removes some of the day-to-day stress. This is why we use a vast array of local and national metal finishing vendors to assist in delivering your products complete while meeting all of your standards.

Our vendor network has extensive experience with MIL specs, AMS standards, aerospace and customer approved sources, and many more.

NADCAP accredited, RoHS compliant, and other certifications are not an issue

Heat Treat

Annealing, Normalizing, Stress Relief, Hardening, Case Hardening, etc.

Metal Finishes

Hard Anodize, Sulfuric Acid Anodize, Chromate Conversion, Chemical Conversion, etc.

Black Oxide, Dry Lube, Electroless Nickel, Electropolish, Nickel, Phosphate, etc.

Gold, Silver, Tin, Zinc, Passivation, etc.

Paint, Powder Coat, Aeroglaze, Lubrite, etc.

Magnetic Particle Inspection

Dye Penetrant

Tensile Strength Testing

Ready to Experience Precision and Excellence?

Ready to elevate your projects with unmatched precision and quality? At Imagineering Machine Inc., we're dedicated to delivering exceptional results. Whether you need precision machining, prototyping, or assembly services, our team is here to exceed your expectations.